Since the founding of the Pfeiffer Group’s timber plant in Lauterbach in 2009, HANSA-FLEX has been the first point of contact there when it comes to hydraulics and the associated services.

05.09.2013

Carved from a very special wood

The aroma of freshly cut wood fills the air as we step out of the car. It’s no wonder. We are in Lauterbach, standing before the gates of the newest production location of the Pfeifer Group which, with its 1,500 employees at nine locations in three countries, is among the most tradition-rich and competitive companies in the European wood industry. Ever since the Lauterbach facility was established in 2009, HANSA‑FLEX has been Pfeifer’s partner of choice when it comes to hydraulics and related services.

After donning our safety vests and protective helmets, we step into the plant grounds. Moving past a truck loaded with logs and huge production halls, we make our way to the maintenance area. There we meet Holger Urban, the head of mechanical maintenance for Pfeifer. While our photographer is busy shooting photos outside, I sit down for a short interview with Mr Urban in the office. Our conversation is frequently interrupted by the telephone or Urban’s colleagues coming into the office to coordinate the day’s work. Mr Urban is a busy man because the maintenance on all of the mobile and stationary machinery has to be planned like clockwork. Equipment availability is the top priority. Nevertheless, he takes a bit of time out to guide me through the entire 50 hectare plant grounds.

From logs to lumber

Our first stop is the in-feed deck. This is where the softwood logs, which can be up to five metres long, are unloaded and undergo a classification. Two workers each operate a hydraulic gripper reminiscent of an oversized version of the three-fingered claw children use to fish toys out of a prize machine. As we watch the activity, a log suddenly turns sideways and threatens to send the next batch of logs flying. For me the close call is exciting but for the workers operating the grippers it is all part of the daily routine. A few seconds later, the log has swung back to the correct position and falls onto the conveyor belt. As it moves along, sensors will measure the timber in three dimensions; a detector will check it for metal, and finally place it in one of more than 100 concrete basins on the plant grounds based on its type, length, and diameter.

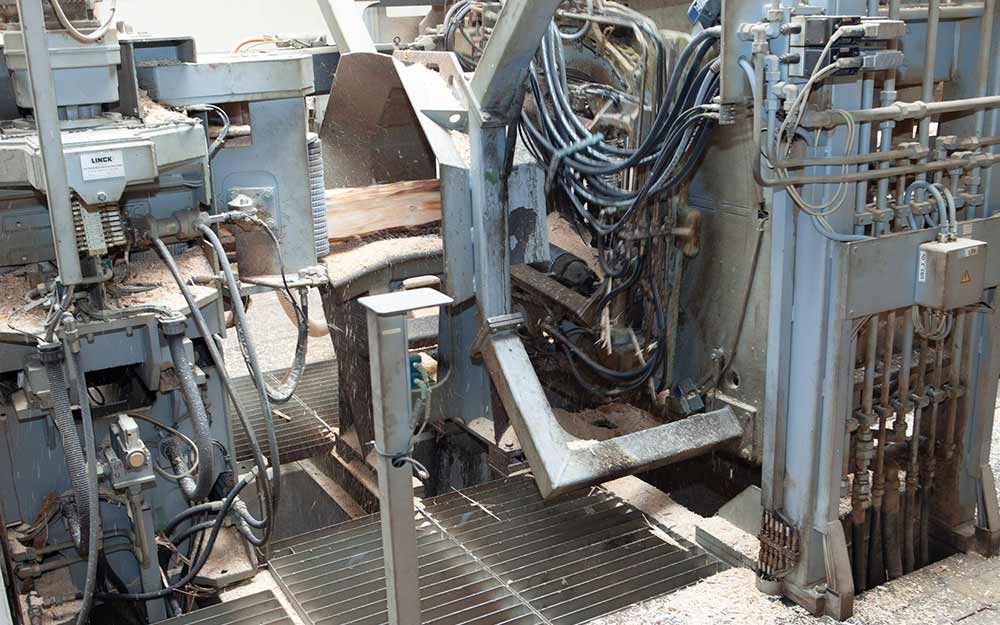

Two excavators are constantly in use at the basins. They empty the basins and stack the contents on piles of logs, grouped by type. Two more excavators transport the logs to the next in-feed area. An employee there keeps watch over log in-feed and the entire sawing line on a row of monitors. Another three-dimensional measurement is made of the wood, it is checked for metal a second time and then carried off on a conveyor belt. Before logs can be processed in the sawing line they are measured a third time. After that, their position is automatically adjusted to optimise subsequent processing. We enter the hall housing the sawing line and for the first time things get very loud. The logs dart by on the conveyor belt. Rotating saw blades cut them to size at a number of different stations until finally the end product, sawn boards for pallets, is created. The process is similar for pallet blocks which are also made at the Lauterbach facility.

Imposing figures

A look at the numbers conveys an idea of the scale of Pfeifer’s production. At the Lauterbach site alone, the company produces 750,000 cubic metres of lumber, 200,000 cubic metres of pallet blocks and 70,000 tonnes of wood pellets. To clarify: a cubic metre of wood refers to a solid cubic metre, not counting any empty space between the layers of lumber. The company’s own on-site biomass power plant is fired with bark and generates 80 million kilowatt-hours of power every year. The heat is used to dry the sawdust, which is later formed into pallet blocks and pellets. Pfeifer uses 100 per cent of the wood that comes through its gates. The only waste is the ash from the biomass power plant. A production facility could scarcely be more environmentally friendly.

The full spectrum of hydraulics

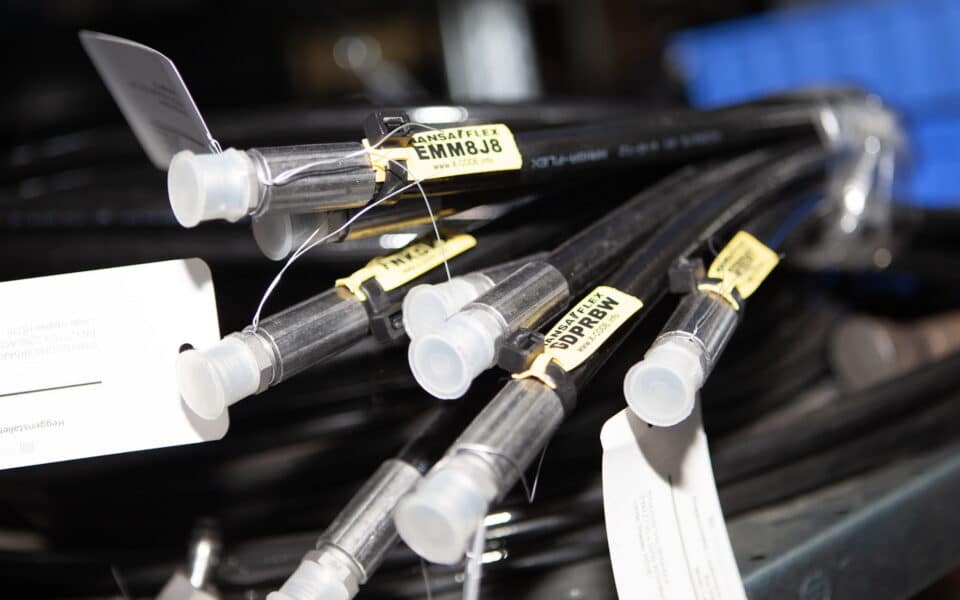

From the grippers at the in-feed deck, to the wheel loaders, excavators, forklifts, and the saw line — hydraulics are everywhere, and so is the connecting equipment from HANSA‑FLEX. A total of 30 high-performance hydraulic power units provide the necessary oil pressure for the various machines. The Fulda branch supplies Pfeifer’s Lauterbach facility with hose lines, couplings, threaded connectors, teflon and industrial hoses, as well as special fittings. To ensure rapid access to replacement parts, Pfeifer’s maintenance department has its own warehouse with HANSA‑FLEX parts which is restocked weekly. “We can meet most of our needs directly from the warehouse. If we need a replacement part in a hurry and it’s not in the warehouse, the HANSA‑FLEX office is very close by. Either they quickly deliver the part or we go pick it up ourselves,” says Urban. And because every hose line is marked with an X-CODE, there are never any mix-ups with orders. “X-CODE is the simplest system. We just read the code, phone it in, and when we show up at the office the part we need is there waiting to be picked up,” says the head of mechanical maintenance.

But HANSA‑FLEX’s service to Pfeifer goes above and beyond just supplying spare parts. External sales representative Carsten Klüh provides advice on non-standard solutions, for instance. “In the saw line, the rotating equipment is constantly moving, which puts severe stress on some of the hoses. To prevent break-downs we used special threaded connectors. This takes the load off of the hoses and increases the time between scheduled maintenance activities,” says Klüh. And that ensures that the smell of freshly cut wood will continue to fill the air in Lauterbach.

Learn more

- 12.03.2024

At home in every field

Agrartechnik Sachsen has been working with HANSA-FLEX for 30 yearsFind out more - 12.03.2024

Masters of the soil

Hans Wübben GmbH tills and retills agricultural and forest land.Find out more - 12.03.2024

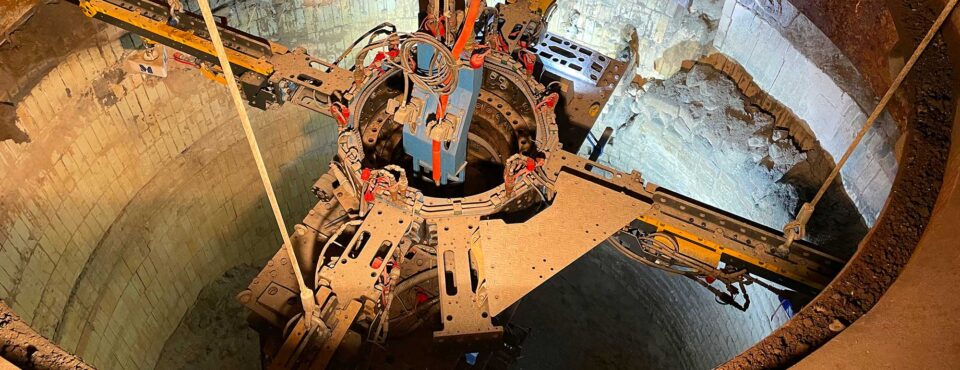

A digital revolution in industrial operations

With its mobile Quadriga platform the M-Group is revolutionising the maintenance of brickwork in industrial furnaces: a remote-controlled robot with a hydraulic hammer carries out previously manual damage-repair work more safely and cost-effectively.Find out more