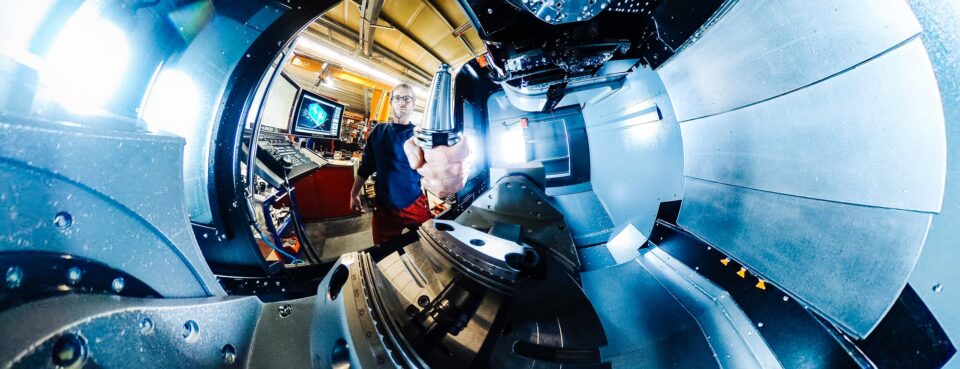

ENGINEERING AND PROJECT PLANNING WITH HANSA‑FLEX

The experienced specialists at HANSA‑FLEX support you in all tasks associated with the engineering and project planning of hydraulic systems and components from design to manufacture. You can rely on our specialist knowledge of fluid technology in the implementation of prototypes, development of hydraulic units and other in-house product developments.

DESIGNED AND MANUFACTURED FOR YOU BY HANSA‑FLEX

Engineered by HANSA-FLEX

HANSA‑FLEX develops high-quality components in-house to its own quality requirements. In this way, we can reliably provide high product quality…

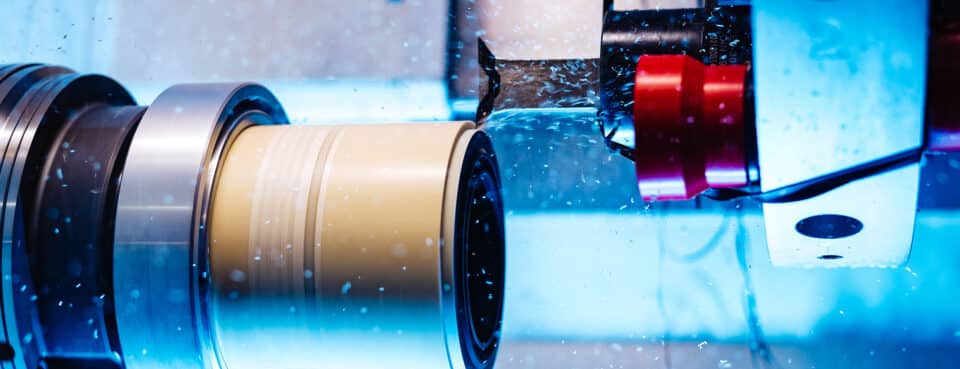

Find out morePrototype manufacture

If you require specific hydraulic components or component groups that are not available off the shelf, the HANSA‑FLEX prototype manufacturing…

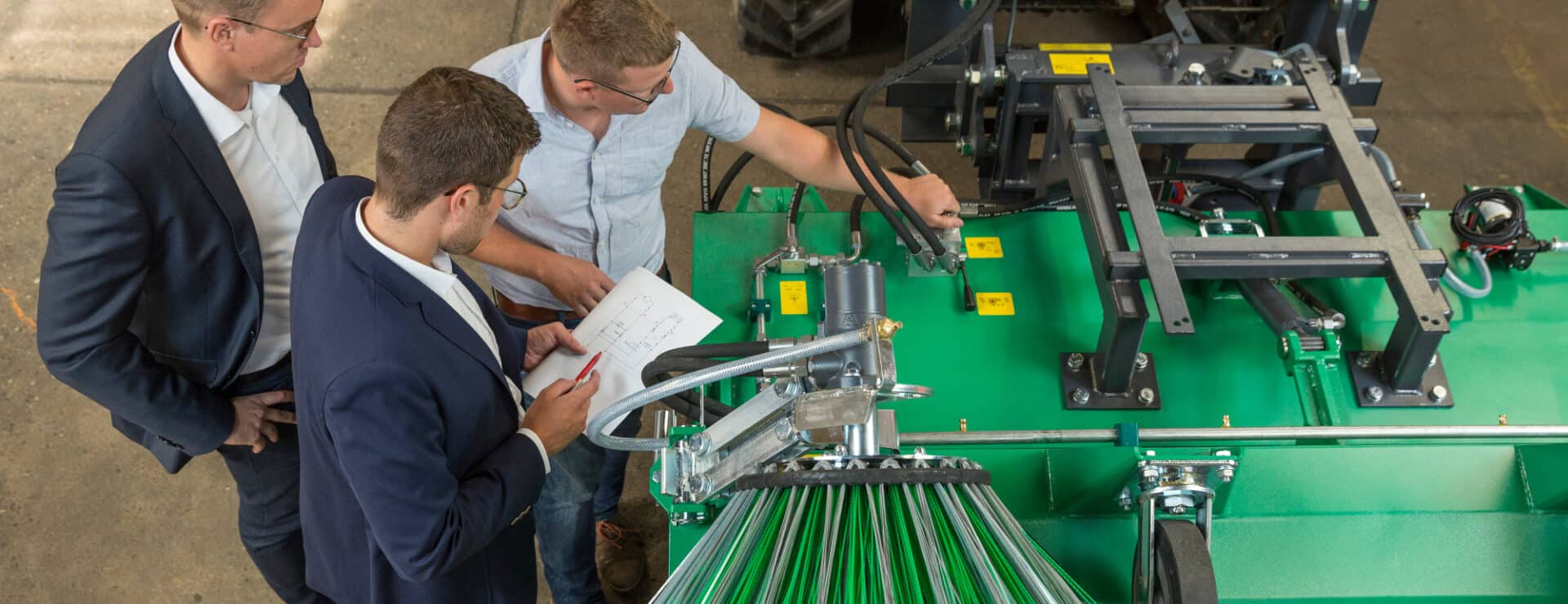

Find out moreHydraulic unit manufacture

Hydraulic power units are the driving force at the heart of many hydraulic systems. Their components include a motor to…

Find out moreA COMPLETE RANGE OF ENGINEERING SERVICES

HANSA‑FLEX Engineering performs in-house development, prototype and power unit manufacture and system design. We are able to support customers at every stage in the development of high-quality products from planning to series production.

Optimum performance

Products engineered by HANSA‑FLEX are designed to work together perfectly.

Expert advice from the very beginning

The HANSA‑FLEX prototype manufacturing team offers specialist knowledge from the first day to series production readiness.

All from the same source

A comprehensive range of services and products for the manufacture of complex power units.

Your data in 3D

We create three-dimensional drawings and models to your specifications.

DESIGNED TO THE LATEST STATE OF THE TECHNOLOGY

Design is elemental to engineering. Our precisely prepared digital design drawings and 3D models make system design much easier and ensure the highest manufacturing quality.

3D models for design and simulation

DOWNLOAD 3D-MODELSUse our 3D models for your system design. We make 3D digital models of our hose line and pipeline components available for you to download. You can integrate these 3D models and CAD product information of components quite easily into your models and design drawings. This saves you time as you do not have to model or draw our components from the catalogue data and you can check the installation and connection situations immediately.

CAD and ECAD for the theoretical design of components

HANSA‑FLEX uses highly capable CAD and ECAD software to create design drawings and circuit diagrams for electrical and hydraulic systems. These systems are designed to meet the customer’s exact requirements. Virtual feasibility checks are made on each drawing, which allows the designers to see whether the project can actually be built in reality. Only when all the theoretical checks have been successfully completed are the data passed to the production floor.

Highest design standards for series production

The 3D drawings produced by our technicians specify the high HANSA‑FLEX quality standard to which the suppliers are to manufacture all the components. Thus we achieve high process reliability and can offer you an optimum price-performance ratio. Regardless of where a component is manufactured, it always has an identical appearance. Standardised production means the likelihood of tolerance errors when manufacturing hydraulic machines and systems is reduced dramatically.

FIND OUT MORE ABOUT IN-HOUSE DEVELOPMENTS AT HANSA‑FLEX

- Premium hose line

- SRS clamp

- Item 1

Best performance under high pressure

HANSA‑FLEX has developed a new series of hydraulic hose lines for high pressures and extreme applications up to 450 bar. It combines maximum performance with a long service life.

- Excellent pressure load capacity, even after 2 million impulse cycles

- Reliable under pressure peaks and dynamic loads

- DNV GL approval for maritime use

- Item 1

Easy hydraulic line installation using the click p

The innovative, modular SRS clamp from HANSA‑FLEX simplifies preassembly before installation. Preassembly requires no tools and offers maximum flexibility due to the clamp system’s modular design.

- Better workplace safety during overhead installation

- Insertion system with engagement hooks enables no-tool preassembly before installation

- For installation on DIN welded-on plates and mounting rails

REMANUFACTURE IDENTICAL VERSIONS OF COMPONENTS AND IMPROVE THEIR DESIGN

Design of replacement parts

You need a replacement for a made-to-measure valve, a cylinder, pipeline or other component but they are no longer available? We scan your component’s geometry using laser technology, create a new design drawing and manufacture the product for you.

- Design and manufacture of all types of fluid technology components

- Exact component geometry captured using a high-precision measuring arm

- Can also be done quickly at short notice, if required

Design improvements

If your machines or systems regularly malfunction, the reason could be a mistake in their design or construction. For example, the bending radii of hose lines and pipelines are often far too small. We check the layout and the technical design of your systems and suggest design improvements where they are necessary. Improving the design can also make your systems more maintenance friendly. We may propose solutions to install hose lines on your systems in such a way that they are more easily accessible. This reduces the cost of regular inspection and component replacement.

THESE TOPICS MAY ALSO BE OF INTEREST TO YOU

Hoses and hose lines

The HANSA‑FLEX range includes hoses for hydraulics and pneumatics as well as for the transport of chemicals, food, air, water and abrasive…

Find out morePipe fittings

Transitions between components in hydraulic systems are always a point for careful consideration. Pipe fittings from HANSA‑FLEX are standardised in accordance with…

Find out moreSealing technology

Hydraulic and pneumatic systems are only as good as their seals. Just one defective seal can lead to long downtimes…

Find out more